Part 145 / MRO Maintenance is Hard

Make it easier with Graymills as a partner

Parts Cleaning For Part 145 / MRO Operations Is...

A Bottleneck

It has to get done, but no one likes doing it. Plus, customers don't like spending money for your A&P to clean parts.

Difficult

Parts have to be clean, but complex parts are hard to do with a brush and a bucket or spray can of cleaner.

A Moving Target

A 172 isn't a Citation. The parts you need to clean will vary from job to job - material, contaminants, geometries.

Why Graymills

Immersion

How It Works: Immersion cleaning involves submerging parts in a tank filled with a cleaning solution. Agitation, heat, and sometimes ultrasonic waves are used to enhance the cleaning process.

Advantages:

Comprehensive Cleaning: Immersion cleaning ensures all surfaces, including hard-to-reach areas and complex geometries, are thoroughly cleaned.

Hands-Off Operation: Many immersion systems are automated, reducing the need for manual intervention and allowing technicians to focus on other tasks.

Versatility: Suitable for a wide range of parts and contaminants, from heavy greases to fine particulates.

Ultrasonic

How It Works: Ultrasonic cleaners use high-frequency sound waves to create microscopic cavitation bubbles in a cleaning solution. These bubbles implode on contact with parts, effectively removing contaminants.

Advantages:

Precision Cleaning: Ultrasonic cleaning is exceptionally effective for delicate and intricate parts, including those with blind holes and tight tolerances.

Consistency: The cleaning action is uniform and penetrates all surfaces equally, ensuring consistent results.

Speed: Ultrasonic cleaners usually provide the fastest turn-around times.

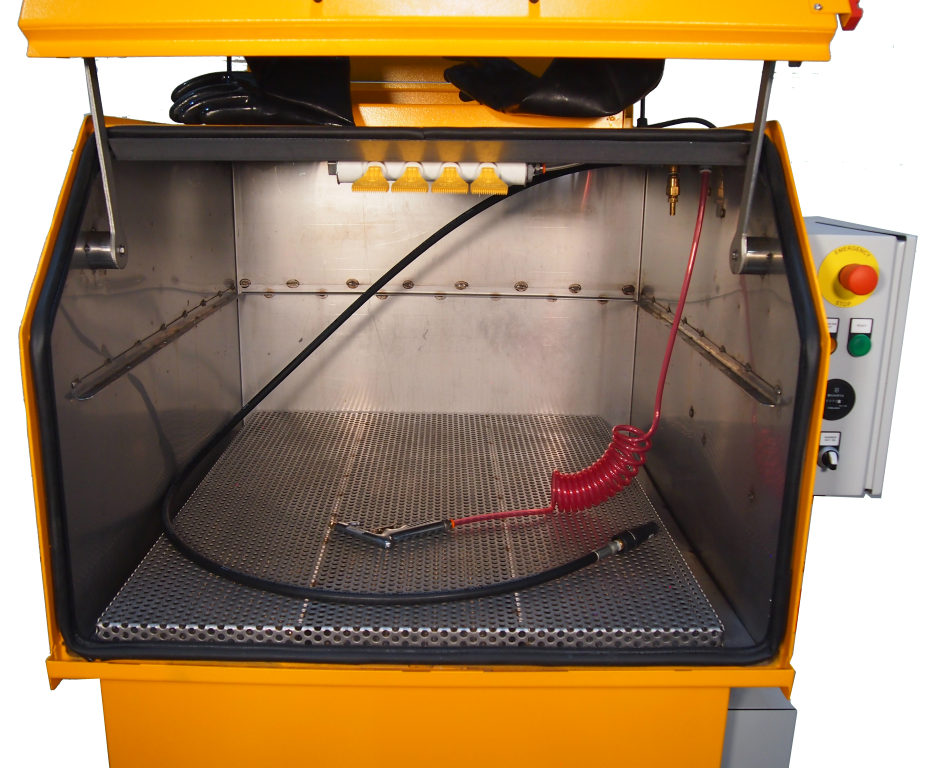

Enclosed Pressure Spray

How It Works: Available in manual or hands-free units, spray cleaning cabinets use medium- to high-pressure nozzles to direct cleaning solutions at parts. The force of the spray, combined with the cleaning agent, dislodges contaminants such as grease, oil, and dirt.

Advantages:

Efficiency: High-pressure spray systems can quickly clean large volumes of parts, making them ideal for high-throughput environments.

Thoroughness: The powerful jets can reach intricate crevices and complex geometries, ensuring a comprehensive clean.

Automation: Some spray cleaning systems are hands-off, reducing manual labor and the potential for human error.

Manual Immersion & Flush

How It Works: Manual cleaning involves using brushes, solvents, and sometimes spray nozzles to manually scrub and wash parts.

Advantages:

Cost-Effective: Manual cleaning systems typically have lower upfront costs and require minimal investment in specialized equipment.

Flexibility: It allows for targeted cleaning of specific areas and is adaptable to various part sizes and shapes.

Simple Setup: Manual systems are straightforward to set up and do not require complex installation or significant space.

Want a free consulatation?

.